7 Steps to Color-Coding in Your Brewery

Color-coding is designating certain colors for tools that should be used in different zones or uses. The purpose is to prevent cross contamination and promote safety and sanitation. Implementing a basic color-coding plan in your brewery doesn’t have to be complicated. Color-coding can be a simple and smart choice to help ensure food safety in your brewery and an important step toward food safety compliance (click here to read our article on how color-coding can be an important part of meeting Food and Drug Administration (FDA) requirements).

There is no industry standard regarding where colors should be used, so color-coding can be implemented in a way that makes the most sense to your brewery. The general rule is to use as few colors as possible. Keep it simple, yet ensure that tools that come in contact with any non-sanitary surfaces (inside or outside of your brewery) do not come in contact with any of your products (hops, grain, yeast, etc.) or surfaces your products touch during the brewing or bottling/canning process.

Reviewing the following steps will help get you on the right track to your own color-coding system.

- Zones or uses?

Is your brewery more easily divided into zones or uses? The layout of your brewhouse may drive this decision. But, even if you do have obvious zones, assigning color-coding by use may still be the best option based on your procedures and workflow. - Review your process.

Systematically review your processes, from when you unload the hops/grains off the truck through fermentation and wash down, to bottling and packaging. You will want to consider special scenarios like if your brewery brews sour and non- sour beer and whether food service is provided – these scenarios require additional measures to prevent cross-contamination. - Identify the tools needed.

Identify the tools needed in each part of your process and how they are to be used in relation to food (or in your case) beer product contact. Don’t forget to consider the storage and placement of your tools – wall racks are key to staying organized, keeping your tools of the ground and proper drying. Our article 10 Essential Tools… can be a great resource to get you covered. - Identify hazard points.

Figure out the points at which hazards to food safety can occur. Examples are stages where unintentional cross contamination may occur like use of cleaning chemicals, wash down processes where unsanitary water may splash, and bottling areas where glass may break. This is an important step for both a comprehensive food safety plan and also for making sure that your color-coded tools are clearly identified for hazard point situations, like cleaning up broken glass. - Assign colors.

The color choice is up to you, but make sure your use of colors is consistent. Some colors are typically designated for certain uses. Black is commonly used for tools used on the floor (brooms) and drains (drain brushes) and other non-sanitary cleaning situations. Breweries commonly use red tools for uses related to cleaning tanks (tank brushes) and graining out (food hoes). Blue is often chosen for cleaning tubes and valves (tube and valve brushes). - Document and communicate.

It is critical to document your color-coding plan and communicate it to all employees both verbally and with reminders of color use posted in your brewery. It’s recommended to implement your color-coding system in its entirety, not piecemeal, to avoid any confusion. Documenting your color-coding system will provide proof of a well thought out effort for food safety for any potential FDA inspections. - Evaluate and adjust.

Like any good plan, evaluating and adjusting to make it more effective and efficient is an important step. Keep a close eye on how your color choices are working for your brewery and make sure they are working best for your processes.

How Union Jack Can Help

Union Jack is proud to offer a unique selection of top quality, FDA-compliant and hygienically designed food handling and cleaning products, specially bundled and hand-picked for breweries. Our color-coded tools are available in up to 12 colors. Most of our tools come in 5 core colors (green, blue, red, white and yellow), and many come in more unique options (pink, orange, purple), plus black. We also offer “total color” options, many of these tools have extra levels of sanitation built in to protect against trapped contagions and hazards such as loose bristles. All of our color-coded tools are designed for easy cleaning.

Color-coding alone is not a complete food safety plan, but it is an important part of one and well worth the effort. If you have any questions, it’s a good idea to consult with an expert. Click here to read more about color-coding, its benefits and why it’s a smart business decision.

Union Jack

Keeping it Clean Since 2006

Recent Posts

-

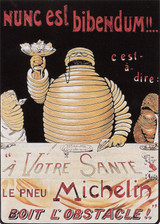

The Origin of the Michelin Guide

From a little red guide book to an iconic standard in international fine dining, have you ever w …Mar 10, 2024 -

Make Color-Coding Your Resolution

Color-coding is a simple way to have a big impact on your facility’s food safety, sanitation and co …Jan 16, 2024 -

Why EPDM Transfer Hoses are a Great Choice for your Brewery

EPDM stands for ethylene propylene diene monomer. It’s a synthetic rubber that has quickly gained t …Jun 14, 2023