Beer is Food - Know Impact Food Safety Legislation on Breweries

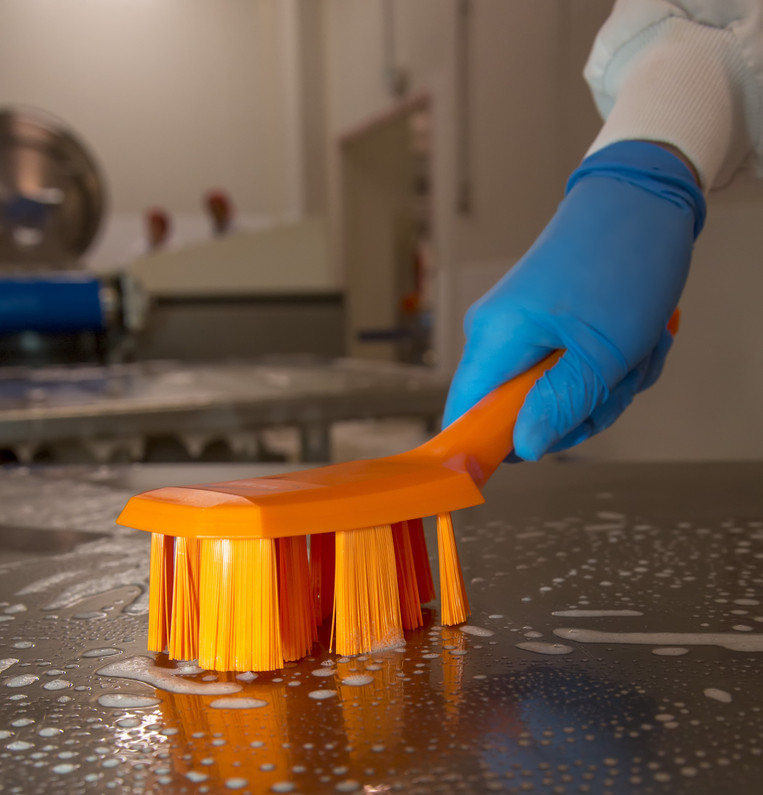

Breweries place a priority on making sure their processes, equipment and brewhouses are sanitary as part of day to day operations. The number of brewery customers buying top quality food safety and cleaning tools is a testament to that, so is the amount of great quality beer out there. With increasing requirements on breweries to comply with federal food safety standards, it’s important to understand the landscape of the most recent legislation and its impact on you.

Food Safety Modernization Act (FSMA)

A little background on how the reform of food safety laws is affecting breweries is a good start. In 2011, the Food Safety Modernization Act (FSMA) was passed. It was a big deal -- the first major overhaul in 70 years. Instead of primarily reacting to contamination in the food processing industry as it had for decades, this legislation was designed to prevent it. As part of the FSMA, beer was categorized as “food” and breweries have since become subject to many of the FSMA’s requirements, including needing to register with the FDA and being subject to FDA inspection.

Many of the specific requirements for breweries are still being developed, but getting ahead of the curve with a thought out and documented food safety plan will help you be better prepared for any FDA inspections and will help you ensure high levels of food safety and sanitation in your brewery.

Food Safety Plan Basics

Here are a couple more acronyms you’ll want to be familiar with:

GMPs (Good Manufacturing

Practices), also referred to as GBPs (Good Brewing Practices)

These refer to the overall plan for quality control to prevent any

health hazards. GMPs ensure that, in all phases of production and storage, your

beer is brewed in a sanitary and safe environment.

HACCP (Hazard Analysis and

Critical Control Points)

HACCP is a 7-principle system that is designed to reduce risks of food

safety hazards. HACCP plans are the steps put in place to support GMPs. This

system works by identifying potential hazards (physical, chemical, biological)

and how to control them at identifiable points in the production process. A

quick note -- you’ll see another similar acronym that is part of the FSMA

legislation, HARPC (Hazard Analysis and Risk Base Preventive Controls). It’s

the same basic concept as HACCP, but encourages the steps to go beyond just

critical control points to the bigger picture of the organization as a whole.

Be Prepared

Make sure you are ready for potential inspections and more stringent requirements, while also creating a safer and more sanitary brewhouse. Taking the time to educate yourself about how the FSMA legislation affects your brewery and implementing a food safety plan (or reviewing and improving upon your current one) is a good idea. A documented and implemented food safety plan shows you’ve thought through your processes and have controls in place to ensure food safety and sanitation in your brewery. Even a very simple plan is better than no plan at all.

How Union Jack Can Help

Visit the Brewery section of our website for food handling and cleaning tools designed specifically to support a comprehensive food safety plan. Our FDA-compliant, hygienically designed color-coded and stainless-steel products are purpose-built for maintaining sanitary and safe environments. Take a look at our 10 Essential Tools… article for key tools to make a part of your safety plan, and our Color-Coding for Breweries article for information about how color-coding can be a simple and smart first step towards food safety compliance.

Important Resources

Here are some great articles about how today’s food safety regulations effect you and what you need to plan for:

- Brewers’ Responsibilities and Obligations under the U.S. Food Safety Modernization Act (FSMA)

- Good Manufacturing Practices for Craft Brewers

- Food Safety Plan for Craft Brewers

- Master Brewers Association of the Americas Food Safety Resources Page

Union Jack

Keeping it Clean Since 2006

Recent Posts

-

The Origin of the Michelin Guide

From a little red guide book to an iconic standard in international fine dining, have you ever w …Mar 10, 2024 -

Make Color-Coding Your Resolution

Color-coding is a simple way to have a big impact on your facility’s food safety, sanitation and co …Jan 16, 2024 -

Why EPDM Transfer Hoses are a Great Choice for your Brewery

EPDM stands for ethylene propylene diene monomer. It’s a synthetic rubber that has quickly gained t …Jun 14, 2023