Make Color-Coding Your Resolution

Color-coding is a simple way to have a big impact on your facility’s food safety, sanitation and compliance. Designating certain colors for tools based on different uses, processes or zones is practical and offers a host of benefits. It prevents cross contamination from allergens, pathogens, chemicals, and physical contaminants -- improving quality control and reducing risk of product recall and related issues. It also increases efficiency by helping with tool organization/storage, tool tracking and eliminating language barriers.

Color-coding is a key element to a Good Manufacturing Practice (GMP) plan and also an important step to reduce risks in HACCP programs. Whether you are a brewery or winery that wants to improve sanitation procedures to meet FDA requirements or a food processor that is putting in place full compliance plans, color-coding is a key component.

Getting Started

Involve your team. Gathering requirements and suggestions based on your facility’s design, functions and processes is a great way to ensure buy-in for a successful implementation. And, don’t forget to consider auditor requirements, if applicable.

ID hazards and allergens. Understanding hazards/risks and any allergens is critical so these issues can be specifically addressed in your color-coding strategy.

Keep it simple. Choosing just a handful of colors to begin with makes your color-coding plan easier to understand and to follow. Colors can be added to build on your color-coding plan as the need becomes necessary.

Training / signage. Taking time to train your team on your color-coding system encourages ownership and offers the opportunity for questions and clarification. Using supporting visuals/signage in the facility is a good way reinforce your plan and serves as reference.

Keep it current. Arrange to check in on your color-coding plan regularly to determined it’s being followed properly and needs are being met to ensure continued success.

Color Choice

Based on use. The most simple strategy is to start by choosing one color for the tools that come into contact with food and a different color for tools that don’t. But, in addition, plan to select a separate color that is only used for cleaning drains and, if applicable, one or more brighter colors specifically for contact with allergens or for use with chemicals.

Based on process. This is a good strategy in facilities where it’s critical that different processes need to be kept separate to prevent cross-contamination, like raw meat vs. cooked meat in a meat processing plant or the canning area vs. the brewing area in a brewery.

Based on zones/departments. This strategy addresses cross-contamination, too, but focuses more on storage and organization -- ensuring the tools stay in their designated areas and making it easy to trace tools used in incorrect areas.

Color Considerations

Total color option. When possible, ensure that the colors of handles match “heads”, block color and bristle color match, etc. This eliminates confusion as to the color designated for a tool. Another way to ensure color continuity is to make sure wall brackets are the same colors as the tools that are hung.

Contrasting colors. Choose tool colors that contrast with your product(s). This will make it easier to identify foreign bodies (like pieces of plastic or bristles).

Be color-blind friendly. Make sure shade differentiation is strong enough. A good way to test this is to use a black and white photo of the tool colors to make sure you can see a strong enough shade difference.

Common Color Selections

Standard colors. Green, Blue, Red, White and Yellow are standard colors that most tools are available in and recommended for tools widely used throughout your facility. Using these standard colors will ensure like colors across all the items you need.

Black for drains. Black is the best color to reserve for the dirtiest jobs, like drains. Our drain brush products have handles marked with a "For Drain Use Only" sticker for an extra way to ensure proper use.

Browns and grays. Browns and grays are popular for use with floors, etc. and are less visible if stored in high traffic areas for frequent use.

Bright colors for high risk. Pink, Purple, Orange and Lime are good examples of colors to use with high contamination risk, chemicals or allergen-related use.

Color-coding with Union Jack

We offer top quality, FDA-compliant and hygienically designed tools in up to 12 colors. Most of our tools come in the five standard colors (Green, Blue, Red, White and Yellow). And, many others come in more unique options (Pink, Orange, Purple and Lime), plus Black which we mentioned is typically designated for drain use. Many of our tools are designed with extra levels of sanitation built in to protect against trapped contagions and hazards, such as the UST line of brushes designed to address loose bristles. All of our color-coded tools are designed for easy cleaning. And, with color-coded tools from Union Jack, you’ll know that you’re using long-lasting products that are designed with food safety and industrial cleaning in mind.

Check out our related blogs:

https://www.unionjacktools.com/blog/understanding-colorcoding-basics/

https://www.unionjacktools.com/blog/7-steps-to-colorcoding-in-your-brewery/

https://www.unionjacktools.com/blog/3-new-colorcoding-options-to-enhance-your-gmpshaccp-plan/

Union Jack

Keeping it Clean Since 2006

Recent Posts

-

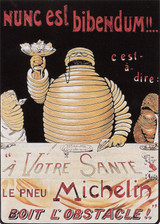

The Origin of the Michelin Guide

From a little red guide book to an iconic standard in international fine dining, have you ever w …Mar 10, 2024 -

Make Color-Coding Your Resolution

Color-coding is a simple way to have a big impact on your facility’s food safety, sanitation and co …Jan 16, 2024 -

Why EPDM Transfer Hoses are a Great Choice for your Brewery

EPDM stands for ethylene propylene diene monomer. It’s a synthetic rubber that has quickly gained t …Jun 14, 2023